esiBlog

Advantages of decentralized drive technology: efficiency, flexibility, and future-proof automation

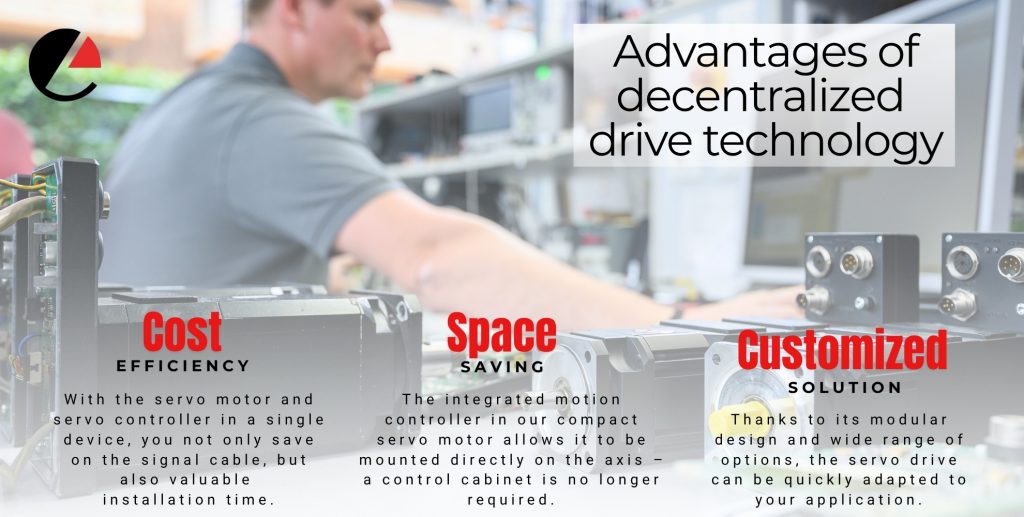

The demands placed on modern production facilities are constantly increasing: greater efficiency, lower costs, shorter installation times and, at the same time, more flexibility. Traditional, centrally designed drive systems often reach their limits here. Decentralized drive technology offers a forward-looking alternative—servo motors with integrated electronics, such as those developed by esitron with the esiMot series.

The advantages at a glance

1. Reduced installation effort

- Fewer cables and connections

- Shorter assembly times

- Fewer sources of error during wiring

2. Space savings in the control cabinet

- Servo controller integrated in the motor

- More compact plant design

- Space freed up for other control technology

3. Cost optimization

- Savings on cables and installation materials

- Less planning and assembly time

- Lower total cost over the life cycle

4. Flexibility and modularity

- Axle-close mounting for individual machine layouts

- Easily expandable and scalable

- Various fieldbus interfaces available (e.g. PROFINET, PROFIBUS, EtherCAT, CANopen, Modbus)

5. Reliability and safety

- Fewer interfaces = greater operational reliability

- Optional safety functions such as Safe Torque Off (STO) + explosion protection

- Robust design for industrial environments

Conclusion: Future-proof solution for mechanical engineering

Decentralized drive technology is more than just a trend—it is a decisive step toward more efficient, modular, and sustainable machine concepts. Those who rely on solutions such as esiMot motors from esitron benefit from lower costs, greater flexibility, and significantly simplified commissioning.

👉 Would you like to learn more?

Visit our product page for the esiMot series or contact us directly—we would be happy to advise you on your individual application.

📞 +49 7541 6000-0 or write to us: sales@esitron.de!